Bleed Air Contamination Simulator BACS

Environment, Hygiene and Sensor Technology

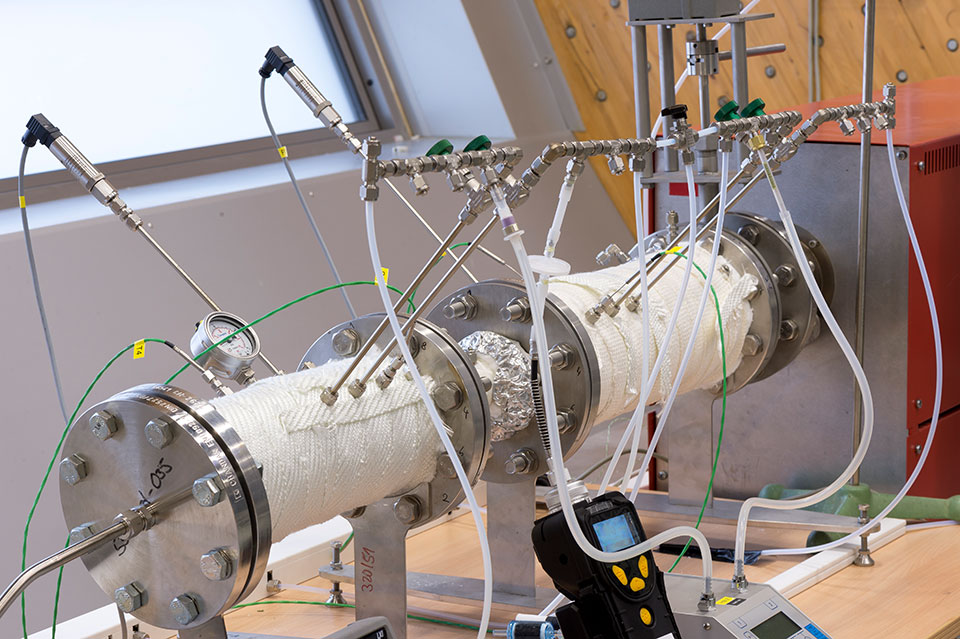

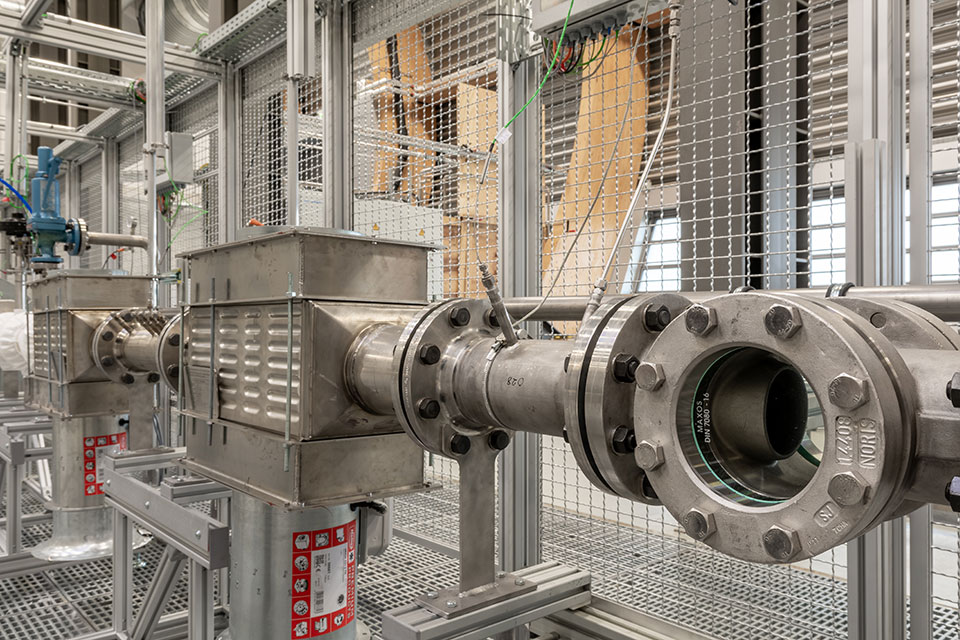

The Bleed Air Contamination Simulator BACS and its little brother sBACS (small Bleed Air Contamination Simulator) are two test facilities that can be used to investigate cabin air contamination from bleed air in jet aircraft and to develop measures to reduce this contamination.

With one exception (B787), the air supplied to the passenger cabin in commercial aircraft and used to regulate the cabin pressure is drawn from the engine (bleed air) or provided by the auxiliary power unit (APU). Under unfavorable conditions, engine and hydraulic oils or deicing fluids can be released into the air and thus into the aircraft cabin, leading to so-called “fume” or “fume and smell events”. These are relatively rare and cannot be predicted under regular operating conditions. Sampling the cabin air on regular flights is not sufficient to identify and quantify the substances that might enter the cabin during a fume event.

The BACS can be used to simulate the pressure and temperature conditions of the air supply and to selectively contaminate the air with oils or deicing agents.

In the high temperature zone, the BACS reaches up to 590 °C at a pressure of 8 bars. The injection port for introducing specific contaminants is also located here. The air is then depressurized from 8 to 3 bars and cooled to 200 °C with the same kind of cooler as used in commercial aircraft. Connections for sensors and online analyzers are located in this mid-temperature zone.

Using a second cooler, the air is further cooled and depressurized from 3 bars down to 1 bar, which cools the air down to room temperature. This zone now simulates the aircraft cabin. A large number of connections are in this section for collecting air samples on different adsorbents for analysis in the laboratory or for connecting up online measuring instruments. Observation windows and ports for isokinetic sampling to determine aerosol particles are also provided.

The sBACS only has a mid-temperature zone (max. 350 °C). As it is not subject to the Pressure Equipment Regulation, it can be modified without the need for an external test and adapted more flexibly to customer requirements. It is particularly suitable for carrying out quick tests on converters, catalytic converters and other devices for purifying the supply air to the cabin during their development. The sBACS can also be used to selectively contaminate the air and take air samples at various points or connect online analyzers and sensors for monitoring air quality.

Technical specifications

| sBACS |

|

| BACS |

|

Simulation data/ measurement technology of the test facility

| Online analyzers |

|

| Air sampling |

|